+ 86-519-83387581

I. Innovation of Automated Processus

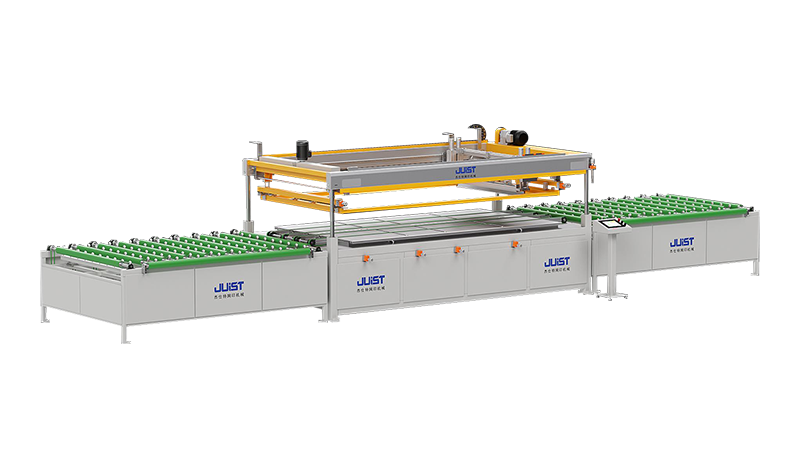

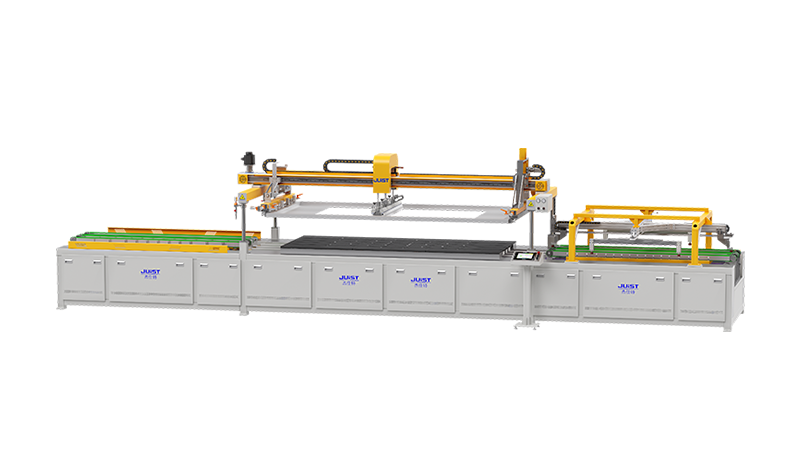

In the traditional coil manufacturing process, from positioning, winding to shaping and testing, each step requires manual operation, which is not only time-consuming and labor-intensive, but also difficult to ensure the consistency and accuracy of each coil. Introductio autem automatic Coil preprocessing apparatus est omnino evertit hoc situ. Per altus integrated automated imperium system, apparatu potest statim perficere totam preprosing processum de coil, a rudis materiam loading ad extremum complevit productum output de spiritu, cum paene non humana interventu in processus.

Positioning precise: Using Advanced sensorem technology et apparatus vision systems, Automatic Coil preprocessing apparatus Potest verius identify et locate in starting situ de coil ad curare accurate de curvis processus.

Efficientis curvis: et constructum-in praecisione motricium et imperium system automatice accommodare curis celeritate, tensio, etc. Secundum ad expositionem parametri ad consequi ieiunium et uniformis exiguam in plano, vehementer improvidus productionem efficientiam.

Intelligens, post curvis, apparatu et statim figura figura et per robotic brachium aut pneumatic fabrica, ut figura coil occurrit consilium requisitis, meliorem altiore et structural stabilitatem.

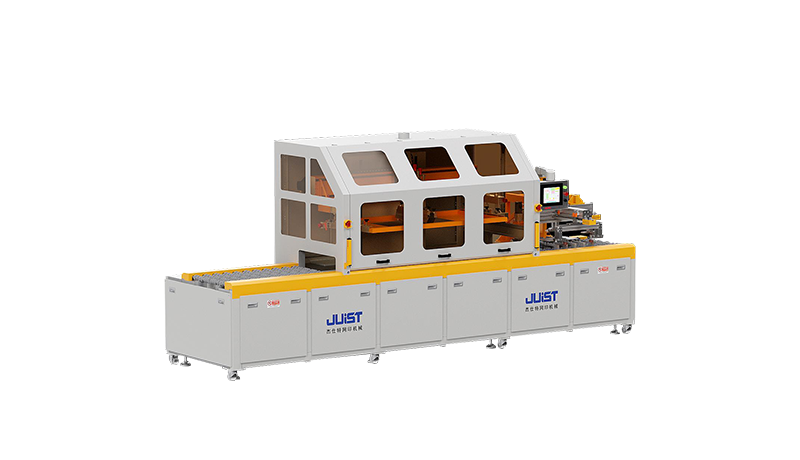

Comprehensive probatio: Denique, automatic coil preprocessing apparatus et ducere a series electrica perficientur probat in coil, comprehendo resistentiam, inductance, in quas inter se observanda, et in occursum ad certa signa et c.

II. Applicationem intelligentes deprehensio ratio

Dum sequi ultimum productionem efficientiam, uber qualitas non neglecta. Quidam provectus exempla latere automatic coil preprecessing machinis instructi instructi intelligentes deprehendatur systems, quae qualis imperium ad novum gradu.

Real-vicis Cras: per integrated summus praecisione sensoriis, variis parametri in coil productio processus, ut temperatus, pressura, tensio, etc., sunt monitored in realem tempus. Semel in deprauationem non invenitur, et metum erit statim edita efficaciter ne productio deficiens products.

Defectus identification: Using Advanced imaginem cognition algorithms, quod intelligentes deprehendatur ratio potest statim identify defectibus, frangit, dissociatis, etc. super superficiem%, cum accurate rate est quam XCIX%, cum accurate rate magis quam XCIX%, ensuring quod omnis coil uit est perfectus.

Data Analysis et Optimization: et collected productio notitia et analysis results potest esse in continua optimization of subsequent productio processibus, productio company ad continue amplio uber et productio costs.