+ 86-519-83387581

In delicata statera pressura imperium

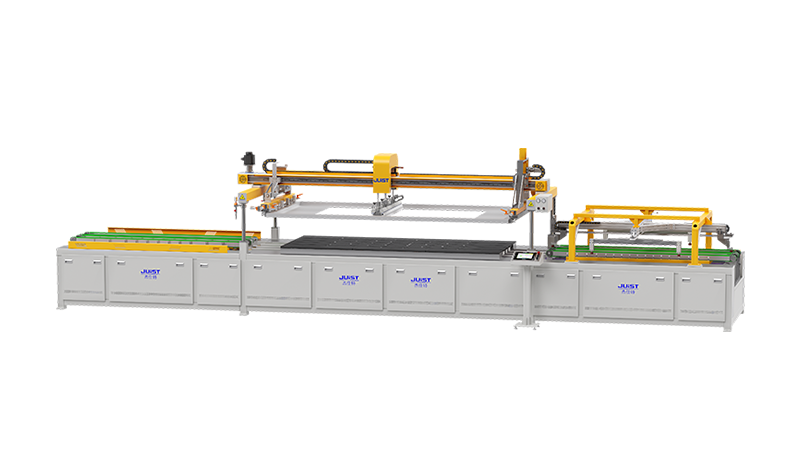

In operationem de Automatic photovoltaic Vitrum tape laminating machina , Pressio est crucial factor. Non directe afficit integritas photovoltaic vitrum et vinculum vires inter tape et speculum. Nimia pressura fiet in "culpit" de fregisset de photovoltaic speculum, praesertim in ore vel infirmi area de speculo. Nimia pressura excedet tolerantia, causing rimas vel etiam completum rumpatur, quod non tantum augetur productio costs, sed etiam graviter afficit salutem et servitium vitae photovoltaic modulorum. On the other hand, if the pressure is too small, the air between the tape and the glass cannot be effectively removed, resulting in gaps on the bonding surface, which in turn affects the firmness and sealing of the bonding, and may cause water vapor penetration in the long run, damaging the performance of photovoltaic cells.

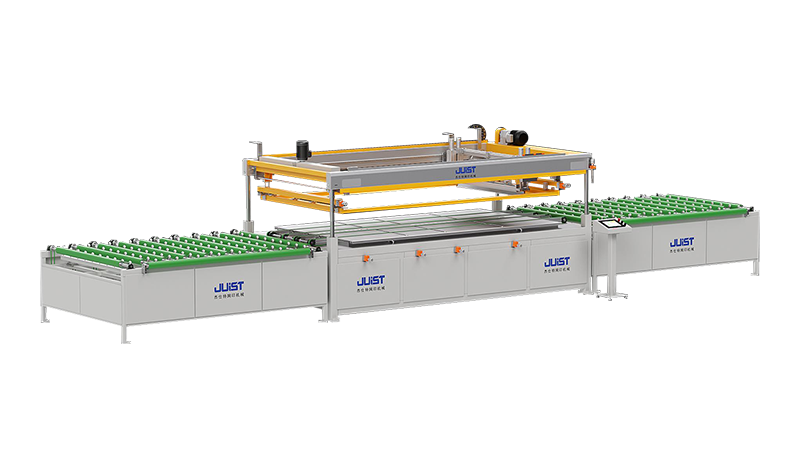

Ideo non est crucial ut per "aureum illud" de pressura imperium. Hoc solet exigit comprehensive consideratione fundatur in viscosity characteres tape materia usus (ut Eva, Poe, etc), in crassitudine photovoltaic vitrum et expectata Lamina. Moderni plene laminating laminating machinis plerumque instructa cum provectus pressura sensoriis et intelligentes imperium systems, quod potest statim adjust pressura secundum ad effectum parametri ad ut quisque laminating potest consequi optimus effectus.

De denique artis temporis imperium

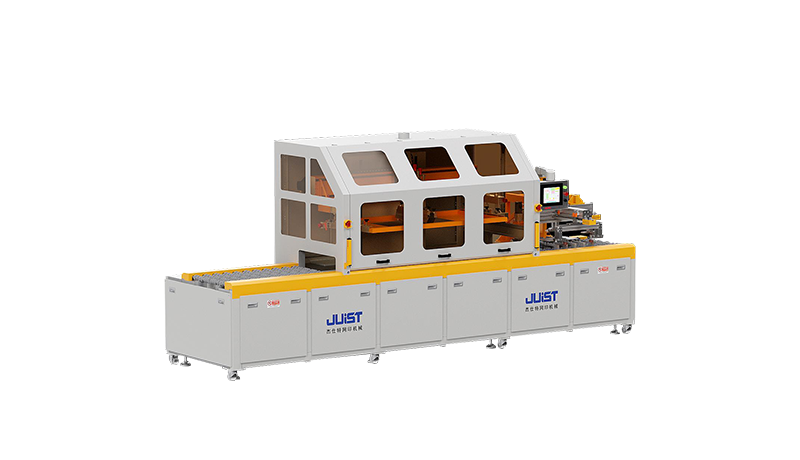

Laminating tempus etiam a factor quod non neglecta. Est directe ad ad gradus ad curandum de tenaces, quod emissiones ad vinculum superficiem et altiore accurate component. Si laminating tempus est brevior, et tenaces non potest plene curari, quod vires est insufficiens, et ut solvere debitum ad vibrationem durante subsequent processui vel translationem. On the contrary, if the laminating time is too long, although it can ensure that the adhesive is fully cured, it may also cause excessive compression of the tape, affecting its resilience and buffering capacity, and even causing micro-damage to the surface of the photovoltaic glass, affecting the optical performance.

Ut consequi optimum laminating effectus, laminating tempus debet esse subtiliter adaequatum secundum ad curationes characteristics in tape, in ambientium temperatus et altiore numero productio linea. Quidam summus finem plene automatic laminating machinis etiam adaptive doctrina munera, quae potest continenter optimize ad laminating tempus secundum historical notitia et realis-vicis feedback ut quisque laminating potest consequi optimus status.

Scientia praxi parametri occasum

In ipsa operatio, ut verius posuit pressura et tempus plene automatic photovoltaic speculum tape torcular, quod est prima necessaria ad plene intelligere perficientur parametri materiae et apparatu usus. Hoc includit sed non limitatur ad genus, crassitudine, et viscosity range de tape, in materia, crassitudine, et vires de photovoltaic vitrum, et maximam pressura, minimum pressura, et temperatus temperatio accurate, calefacit modum, et temperatus temperatio range, calefacit modum, et temperatus temperatio accurate, calefacit modum, et temperatus temperatio range, calefacit modum, et temperatus imperium range.

Secondly, through small-scale experimental pressing, gradually adjust the pressure and time parameters, observe and record the pressing effects under different parameter combinations, including bonding strength, appearance quality, production efficiency, etc. Based on these data, the pressure-time-quality relationship curve can be drawn to find the optimal parameter combination.

Denique verificatur meliorem parametri sunt initus in imperium system de torcular ad animadverto an automated et mensuris productionem processus. Simul a ordinarius metus et calibration mechanism constat ut diu terminus firmum operatio torcular et ponere consistency de pressing quality.